Company

Since its founding in 1960, SOMO has always pursued high levels of innovation, and soon complemented its traditional hydraulic torsion bar press brakes with a series of synchronized oleodynamic press brakes.

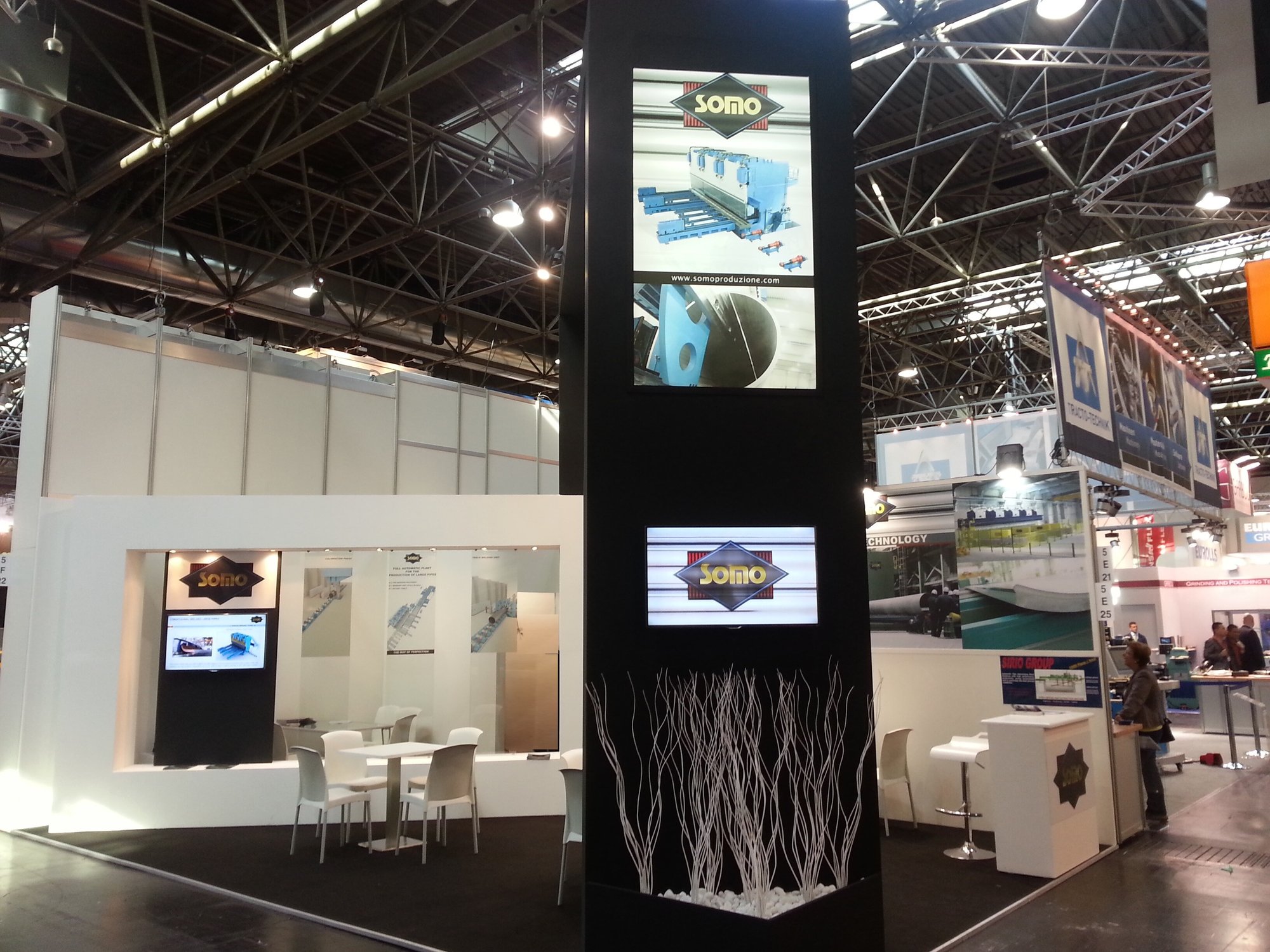

Structural quality, safety and reliability have always distinguished SOMO, which,with a long term vision , chose to set itself off against standardization. In fact, one of the features that make SOMO Produzione SPA unique is the high grade of customization of its machinery: each machine is designed following the customer's instructions and requirements, leading to a very high degree of satisfaction.

In the latter part of the 1990s, following an internal restructuring, SOMO increased its drive for innovation even more and began to focus toward the production of plants dedicated to specific products, such as large pipes and poles.

From that breakthrough moment, SOMO began manufacturing bending plants up to 9,000 tons and press brakes between 300 and 3,000 tons dedicated to specific products.

The experience and know-how capitalized, make SOMO a reliable and competent partner for clients who cannot find a solution on the market that meets their needs.

By choosing SOMO, you choose to rely on a company that will support you at every stage of your project, from plant selection and commissioning to installation and after-sales service.

Technology and user-friendliness

Since its earliest years, SOMO has been among the most cutting-edge companies in the industry, always keeping a close eye on the latest technological developments. Constantly updated high technology is combined with the ease of use of SOMO's machines and plants: these two features ensure that every SOMO machine has a high degree of reliability and guarantee productivity that is hard to find in other equivalent machines.

.jpg)

Low maintenance

Thanks to our high level of know-how and our use of state-of-the-art technology, SOMO machines enjoy a very high level of reliability: once installed, you can almost forget about us, but should you need maintenance you can rely on the prompt intervention of our qualified technicians.

Energy efficiency

Our press brakes are designed with a focus on energy efficiency. We use motors and control systems that optimize energy consumption, predictive maintenance systems, and the latest materials and lubricants, thus reducing operating costs and environmental impact. This enables our customers to operate more sustainably and responsibly.