Pipe Cladding Machines

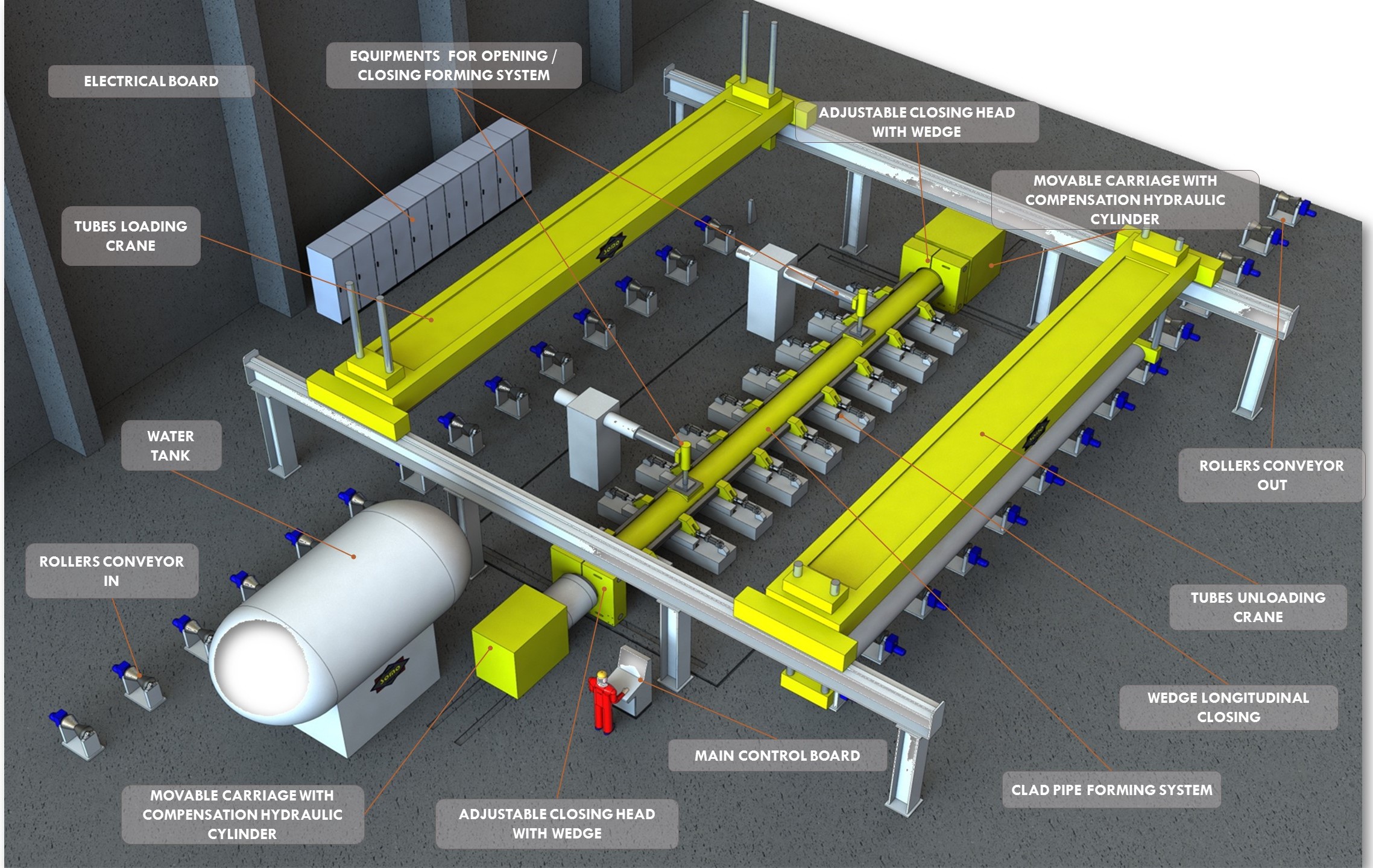

SOMO manufactures hydroforming pipe cladding machines ideal to clad an outer carbon steel pipe with an inner stainless steel pipe (Inconel).

In the pipe cladding process, corrosion of tubular products is a typical problem due to acidic working environments. In these settings, bimetallic piping (BP), consisting of a low-carbon steel base layer and a corrosion-resistant alloy (CRA) liner layer, is an affordable and reliable anti-corrosion technology.

Using a pressure of 1,000 bar, the hydroforming pipe cladding machine allows the two tubes (outer tube + inner liner) to be deformed to make them bond together.

Strenghts

Ease of use

High accuracy

.png)

Extreme automation

Technical data

With our state-of-the-art pipe cladding machinery, we offer our customers the possibility to produce CLAD pipes starting from Inconel inner liner and Carbon Steel outer pipe.

We distinguish ourselves with our ability to provide highly customized technical data adaptable to our customers' unique needs, ensuring that each customer gets exactly what they need.

Advantages of SOMO pipe cladding machines

SOMO’s pipe cladding machines are designed for precision, reliability, and compliance with international standards. Our equipment is used by manufacturers worldwide to deliver consistent results in industrial-scale applications.

Here’s why our customers choose SOMO:

- Global Certifications: all SOMO pipe cladding machines are built to meet local safety and performance certifications, ensuring smooth implementation across different countries.

- High-Quality yet Affordable: we maintain a strong market position by delivering top-tier cladding solutions at competitive prices, with no compromise on quality or durability.

- Warranty & Lifetime Maintenance: every pipe cladding machine comes with a one-year warranty and lifetime maintenance support, offering peace of mind and long-term investment protection.

- Complete Service Structure: we provide a dedicated service team offering:

- Pre-sale consultation

- Support during installation and commissioning

- After-sale assistance, including remote and on-site diagnostics

- We are committed to responding to all technical or commercial inquiries within 8 hours.

- Pre-sale consultation

SOMO’s reputation in the pipe cladding machine industry is built on trust, technological innovation, and client support.

Applications of pipe cladding process

The pipe cladding process plays a vital role in industries where corrosion resistance, mechanical strength, and thermal protection are essential.

Common applications:

- Oil & Gas: internal and external cladding of pipelines to resist corrosive substances and pressure fatigue.

- Chemical Processing: protecting pipe interiors against aggressive chemicals and high temperatures.

- Power Generation: enhancing the durability of pipes in boilers, turbines, and heat exchangers.

- Marine Industry: shielding pipelines from seawater corrosion in offshore platforms and ships.

- Water Treatment: cladding for stainless steel piping systems in desalination or purification plants.

SOMO’s pipe cladding machines are engineered to support high-precision overlay welding and automatic cladding in these demanding fields. The process ensures long-term performance of base pipes with minimal maintenance.

FAQs

1. What is pipe cladding?

Pipe cladding is the process of applying a protective layer—often using corrosion-resistant alloys (CRA)—onto the surface of a base metal pipe. The goal is to combine the mechanical strength of the base pipe with the chemical resistance of the cladding layer.

This pipe cladding process enhances durability and significantly reduces the need for full exotic alloy construction, lowering material costs.

2. What are the parts of pipe cladding machines?

A typical pipe cladding machine includes:

- Cladding head: carries the welding torch or deposition tool

- Rotating system: ensures the pipe is uniformly processed

- Control system: often CNC-controlled for precision

- Wire feeder: supplies filler material during cladding

- Cooling units and shielding gas systems, depending on the application

SOMO machines are customisable and designed to integrate seamlessly into automated production lines.

3. What is pipe insulation?

Pipe insulation is a different process where insulating materials are applied to pipes to retain heat, prevent freezing, or improve energy efficiency. Materials commonly used include fiberglass, mineral wool, and polyurethane foam.

4. What are the Differences Between Pipe Insulation and Pipe Cladding?

|

Feature |

Pipe Cladding |

Pipe Insulation |

|

Purpose |

Corrosion and wear resistance |

Thermal and sound insulation |

|

Material |

Metal overlays (CRA, stainless steel, etc.) |

Fibreglass, foam, mineral wool |

|

Application Method |

Welding, metallurgical bonding |

Wrapping, spraying, or gluing |

|

Target Industries |

Oil & gas, power, chemical |

HVAC, plumbing, energy conservation |

While both processes protect pipes, cladding is structural and anti-corrosive, while insulation is thermal and energy-saving.

5. What is the CRA cladding process?

CRA cladding (Corrosion Resistant Alloy) is a subtype of the pipe cladding process in which a high-alloy material such as Inconel, Hastelloy, or Duplex Stainless Steel is bonded to a lower-cost base metal like carbon steel.

This process enables:

- Enhanced chemical resistance

- Resistance to abrasion, pressure, and high temperatures

- Extended service life in critical applications

CRA cladding is often performed using GMAW, GTAW, or SAW processes, and SOMO’s machines are fully compatible with these techniques.

SOMO, your partner in cladding processes

With over 30 years of expertise, SOMO Produzione is a leader in designing and manufacturing pipe cladding machines that meet the toughest industrial demands. From single-head machines to fully automated production lines, we offer:

- Custom engineering to match your workflow

- Installation and training worldwide

- Integration with existing pipe forming systems

By choosing SOMO, you’re not only investing in high-performance machinery—you’re also gaining a long-term technical partner committed to your success in every phase of the pipe cladding process.

Standards

SOMO machinery complies with the following regulations:

- Machinery 2006/42/EC

- Electromagnetic Compatibility 2004/108/EC.

Conctant us for further information about our pipe cladding machines

Plants for pole production

Bending presses and complete plants for processing poles of any height and diameter.

Special applications

Plants made according to specific customer's requirements, equipped with customized equipment and devices.

Our services

We perform spare parts and maintenance services on all types of plants, including ones not built by SOMO

Spare parts

We supply and guarantee original spare parts for every type of machine, from the newest to the oldest. Our sales team is available to guide you to the perfect spare part for your machine.

Revamping

Find out how your machine can be improved by integrating the latest technologies available on the market: a complete renovation of components, mechanical and electronic, and the installation of new management software will give new life to your old SOMO machine.

Maintenance and service

Our technical team is always by your side, even in times of trouble: whether on-site assistance or minor maintenance, you can rely on SOMO.

Remote assistance

Thanks to the remote access setup, in case of breakdown or malfunction, SOMO's technical team will be able to intervene in a timely and accurate manner.