Pole Welding Machine

Pole welding machine for poles and polygonal towers

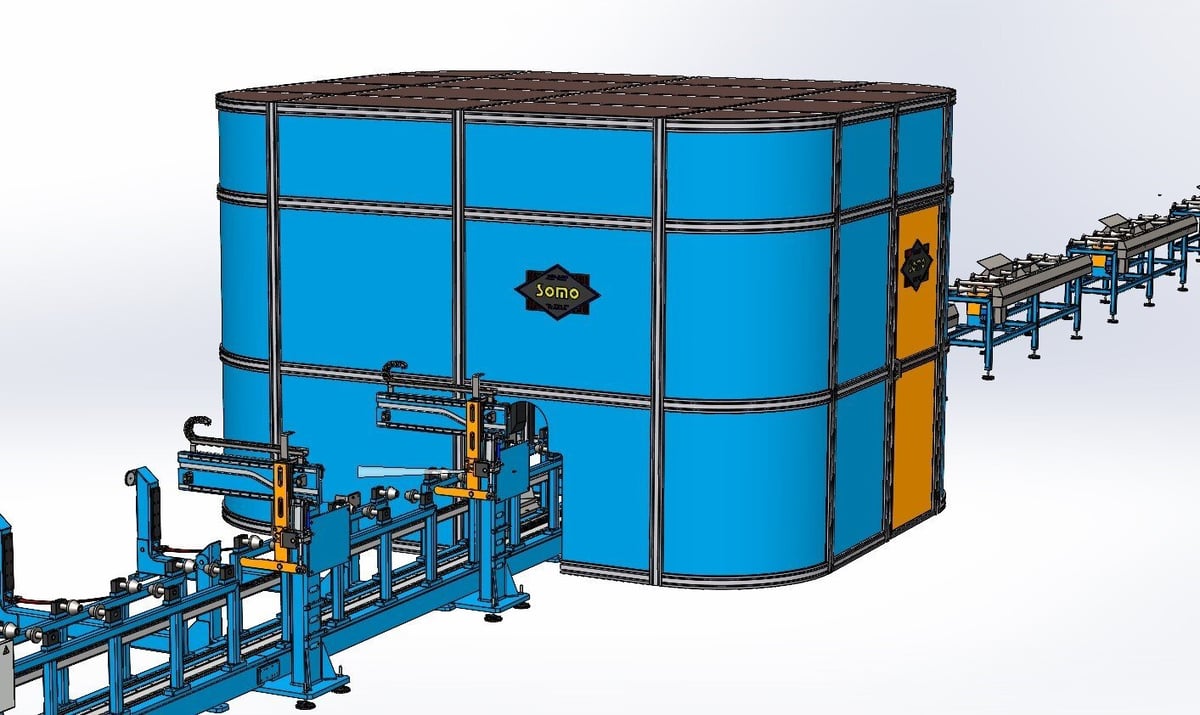

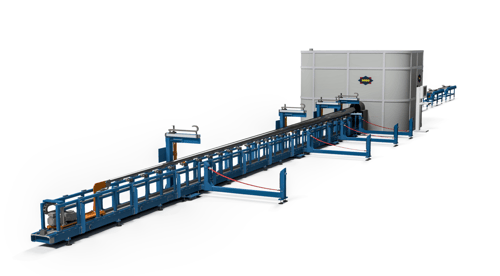

Discover our advanced laser pole welding machine, an automatic system designed for the continuous closing and welding of round poles. This solution integrates lateral and vertical hydraulic presses managed by numerical control (CNC), ensuring precise alignment of the pole edges and efficient continuous welding without the need for filling material.

Besides, our pole welding machine offers a fully automatic system tailored for the continuous closing and welding of both single- and double-shell polygonal poles. Featuring CNC-managed lateral and vertical hydraulic presses, this solution guarantees accurate edge alignment and continuous welding using MIG/MAG or submerged arc welding processes. Ideal for polygonal towers and large-scale pole structures, this machine ensures reliability and optimal performance.

Strenghts

Ease of use

High accuracy

.png)

Extreme automation

Technical data

With our state-of-the-art machinery, we offer our customers the capability to manufacture poles in strict compliance with international standards.

We distinguish ourselves with our ability to provide highly customized technical data adaptable to our customers' unique needs, ensuring that each customer gets exactly what they need.

Pole Welding Machine for High-Performance Production

Our pole welding machine is engineered to deliver efficient and precise welding for round conical poles. With an automatic system powered by CNC-controlled closing wheels, it ensures perfect edge alignment and continuous welding. Designed for industrial-scale operations, this solution increases productivity and improves weld quality.

Automatic Pole Welding Machine for Round Poles

The automatic pole welding machine for round poles features a high-speed continuous welding process that requires no additional filling materials. This system includes vertical and lateral closing wheels for seamless edge alignment, guaranteeing consistent weld integrity. Ideal for applications such as lighting poles and structural supports, it offers unmatched reliability and efficiency.

Why Choose Our Pole Welding Machine?

- Automatic continuous welding for enhanced productivity.

- No addition of material the result is a smooth,uniform and flawless joint.

- Low energy consumption compared to other welding technologies.

- Laser welding is faster than other methods, increasing productivity and reducing processing times.

Optimize Your Pole Production with Our Advanced Welding Solutions

Our pole welding machines are designed to streamline production, reduce errors, and deliver consistent results. Contact us today to learn how we can support your manufacturing needs.

Plants for pipe production

Longitudinally welded pipe (LSAW) plants, suitable for a wide range of applications.

Special applications

Plants made according to specific customer's requirements, equipped with customized equipment and devices.

Our services

We perform spare parts and maintenance services on all types of plants, including ones not built by SOMO

Spare parts

We supply and guarantee original spare parts for every type of machine, from the newest to the oldest. Our sales team is available to guide you to the perfect spare part for your machine.

Revamping

Find out how your machine can be improved by integrating the latest technologies available on the market: a complete renovation of components, mechanical and electronic, and the installation of new management software will give new life to your old SOMO machine.

Maintenance and service

Our technical team is always by your side, even in times of trouble: whether on-site assistance or minor maintenance, you can rely on SOMO.

Remote assistance

Thanks to the remote access setup, in case of breakdown or malfunction, SOMO's technical team will be able to intervene in a timely and accurate manner.

Standards

SOMO machinery complies with the following regulations:

- Machinery 2006/42/EC

- Electromagnetic Compatibility 2004/108/EC.

Applications