Light Pole Machine Roto System

Light Pole Machine Roto System: Advanced Technology for Aluminum Poles

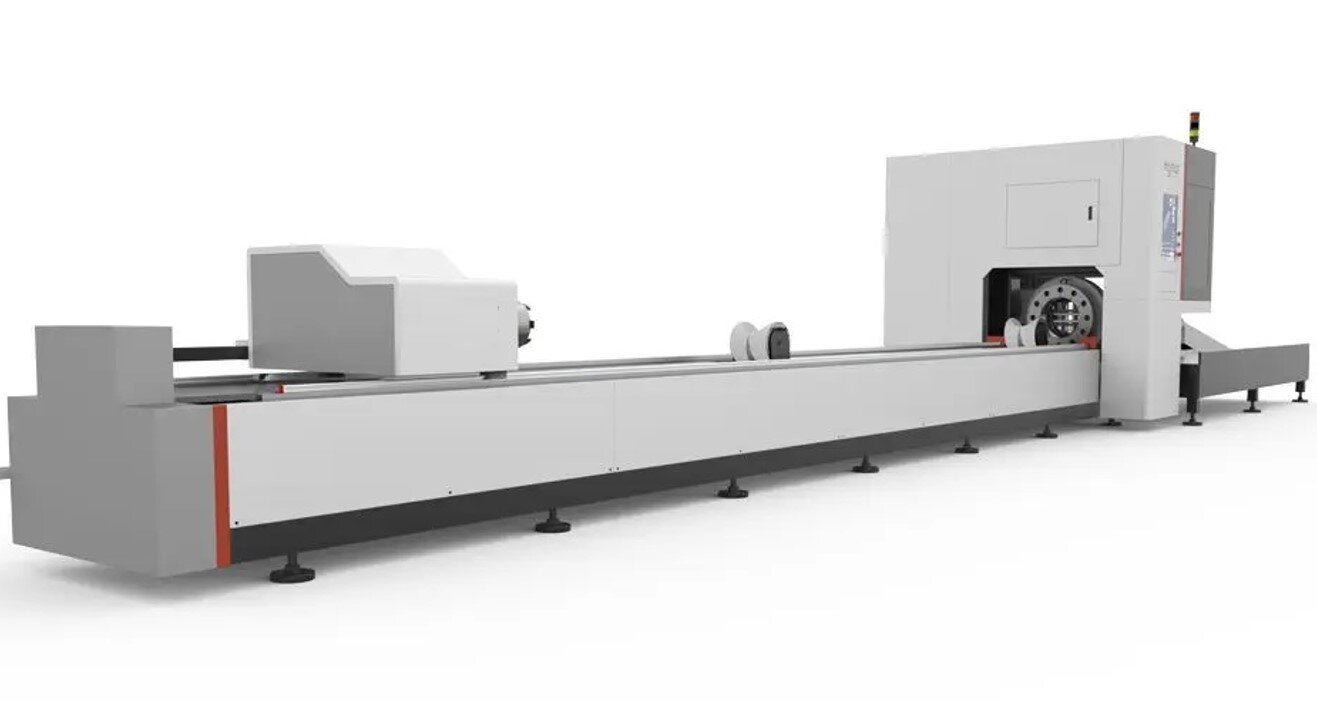

The Roto System is a high-performance light pole machine designed for the production of aluminum lighting poles and flagpoles. Starting from a cylindrical aluminum tube, the machine processes the material to create conical poles with various shapes and dimensions.

This process involves turning, also known as lathe spinning, where the tube is deformed by pressing its walls against a shaping tool. The result is a symmetrical, conical pole with a smooth axial profile—ideal for public lighting, infrastructure, and urban design projects.

Strenghts

Ease of use

High accuracy

.png)

Extreme automation

Technical Features of the Roto Light Pole Machine

Our state-of-the-art light pole machine allows for the production of CLAD pipes starting from Inconel inner liner and Carbon Steel outer pipe. We pride ourselves on offering fully customizable solutions: our technical configurations are tailored to meet the specific production needs of each customer, ensuring precision, performance, and reliability.

ROTO SYSTEM

RAW MATERIAL (ALUMINUM TUBE)

|

Parameter |

Min |

Max |

|

Diameter |

120 mm |

280 mm |

|

Length |

2.500 mm |

9.500 mm |

|

Thickness |

3 mm |

6 ÷ 10 mm |

FINAL COMPONENT (ALUMINUM CONICAL POLE)

|

Parameter |

Min |

Max |

|

Diameter |

60 mm |

280 mm |

|

Length |

3.000 mm |

14.500 mm |

|

Thickness Reduction |

25% of raw material thickness |

Applications and Sectors of Use for Light Pole Machines

A light pole machine like the Roto System is essential for a wide range of applications. It is used in the production of poles for street lighting, highways, parking lots, airports, ports, and sports facilities. These poles are also commonly installed in modern urban design projects, where aesthetic and structural quality must go hand in hand. Thanks to its flexibility, the Roto System can meet the production needs of both public infrastructure and private industrial projects.

Why Choose Aluminum for Light Pole Production

Aluminum is one of the most suitable materials for light pole manufacturing, and the Roto System is specifically engineered to enhance its properties. Lightweight yet strong, aluminum resists corrosion, making it perfect for outdoor environments exposed to varying weather conditions. It is also 100% recyclable and easy to shape, allowing the light pole machine to produce consistent, high-quality conical poles with reduced material waste and lower energy consumption.

Starting a Light Pole Production Plant: How SOMO Produzione Can Help

Setting up a light pole production plant requires the right technology, workflow planning, and reliable partners. The Roto System light pole machine is designed for easy integration into new or existing facilities, offering flexibility, efficiency, and low operational costs. Whether you're starting from scratch or expanding your current setup, SOMO Produzione provides full support—from feasibility studies and plant layout design to training and after-sales assistance—helping you build a competitive and future-ready manufacturing line.

Plants for pipe production

Longitudinally welded pipe (LSAW) plants, suitable for a wide range of applications.

Special applications

Plants made according to specific customer's requirements, equipped with customized equipment and devices.

Our services

We perform spare parts and maintenance services on all types of plants, including ones not built by SOMO

Spare parts

We supply and guarantee original spare parts for every type of machine, from the newest to the oldest. Our sales team is available to guide you to the perfect spare part for your machine.

Revamping

Find out how your machine can be improved by integrating the latest technologies available on the market: a complete renovation of components, mechanical and electronic, and the installation of new management software will give new life to your old SOMO machine.

Maintenance and service

Our technical team is always by your side, even in times of trouble: whether on-site assistance or minor maintenance, you can rely on SOMO.

Remote assistance

Thanks to the remote access setup, in case of breakdown or malfunction, SOMO's technical team will be able to intervene in a timely and accurate manner.

Applications